Silicone Compression Molding

Specialty Manufacturing, Inc. (SMI) specializes in low and medium volume silicone rubber compression molding runs to create a variety of parts, including gaskets, seals, and intricate medical components. The increased production rate, shortened lead times and less expensive tooling make this silicone compression molding process more economical for prototypes, short runs, flat sheets and start-up production.

Compression molding is one of the most common silicone molding techniques, and it is a time-tested and effective SMI molding process. Parts constructed using a silicone compression molding process tend to be free of residual stress and highly detailed. This is why silicone compression molding is so common in the production of parts for the medical, research, and lighting industries that SMI serves.

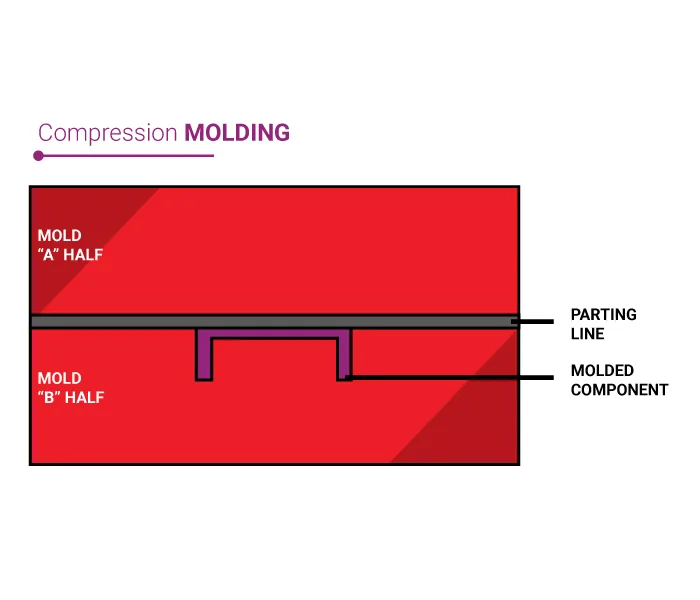

What is silicone compression molding?

Silicone Compression molding is the process of placing un-vulcanized LSR material into the cavity of each half of the mold. The mold is then assembled, placed into a heated compression molding press, and cycled. Silicone is vulcanized through this compression molding process and a part is formed. While this silicone molding process itself is somewhat slower than injection molding, it does yield quick turns on prototype or R&D phase parts as well as less costly tooling upfront. SMI uses silicone molding processes, like compression molding, to ensure precision and quality.

Micromolding Medical Components for Small Volume Parts

Taking advantage of compression molding processes and advanced silicone molding techniques, SMI specializes in producing micromolded medical components for small volume parts with complex details that require tight tolerances.The addition of a silicone overmold onto your plastic, metal, or silicone part can provide both a cushion and seal, which is essential to prevent debris, other biofluids, and even electrical current from passing through a medical device or instrument. Our silicone parts manufacturing process allows us to plasma etch metal and plastic parts in-house. The plasma etching process cleans the surface and creates a waterproof barrier, which also provides maximum adhesion and bonding for the silicone overmold.

Silicone Compression Molding for LED Lighting

For low volume LED lighting applications, our optically clear silicone replaces glass as the ideal material due to increased transparency and flexibility. This silicone compression molding process enables engineers to develop innovative designs and small-run manufacturing methods which were previously out of reach.

Ready to Get Started?

Find out how SIM’s silicone molding techniques and compression molding processes, can create

high-quality silicone parts for medical, industrial, and research applications.